In industrial environments, every inch of vertical space can be critical. For businesses operating in facilities with limited headroom, standard lifting equipment often falls short, compromising efficiency and safety. This was precisely the challenge faced by a valued client in Australia, who required a robust and precise lifting solution that could perform optimally within their specific structural constraints. DQCRANES, a leading provider of advanced material handling equipment, rose to the occasion, delivering two custom-engineered three-phase low headroom electric chain hoists designed to meet their exacting specifications.

The Challenge

Our Australian client, a prominent player in the fabrication sector, approached DQCRANES with a clear requirement: to maximize the effective lifting height within their existing operational space. Their facility presented typical challenges associated with older or purpose-built structures – lower ceilings than ideal for conventional lifting operations, yet a critical need for efficient material transfer of heavy loads.

Key challenges included:

- Limited Headroom: Standard electric chain hoists would significantly reduce the available lifting height, hampering production flow and potentially requiring costly structural modifications.

- Precision and Control: The client’s operations demanded precise positioning of loads, necessitating a hoist with reliable single-speed control.

- Robust Performance: As a busy industrial facility, the hoists needed to be durable, reliable, and capable of continuous operation under demanding conditions.

- Power Supply: The hoists needed to be compatible with Australia’s standard three-phase industrial power supply.

Low Headroom Hoist Solution – DQCRANES

Understanding these critical requirements, the engineering team at DQCRANES meticulously designed and manufactured a bespoke lifting solution. We provided two three-phase electric chain hoists, specifically tailored to the client’s operational environment.

Design Details:

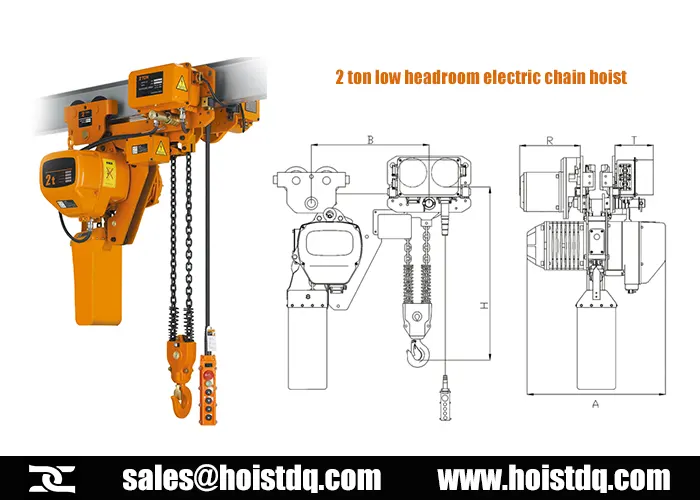

- Type: 2 Ton Low Headroom Electric Chain Hoist

- Power Supply: 400V/50Hz/3-Phase

- Lifting Height: A crucial 4.5 meters (approximately 14.76 feet) – expertly designed to maximize the vertical reach within the client’s limited headroom, allowing for greater operational flexibility and storage capacity.

- Lifting Speed: Single Speed, precisely calibrated at 6.6 meters per minute (approximately 21.65 feet per minute). This speed was chosen to offer a perfect balance of efficiency for general material handling and sufficient control for delicate or precise lifting operations.

- Design: The integrated design of the low headroom hoist minimizes the distance between the hook and the beam, effectively “gaining” valuable vertical space that traditional hoists cannot.

Our commitment to quality ensures that every component, from the robust motor to the durable chain and gearbox, is engineered for longevity and consistent performance, adhering to international and Australian safety standards. The three-phase power supply ensures stable and powerful operation, essential for continuous industrial use.

Seamless Delivery & Installation Support

Finished manufacturing and loading test, DQCRANES delivered the 2 ton electric chain hoists on time and provided installation guidance and remote support to the Australian client. The hoists were delivered in protective packaging, including full technical manuals, wiring diagrams, and certification documentation for hassle-free commissioning.

The Impact

- Maximized Usable Space: By reducing the headroom required, the client gained valuable vertical space, allowing for higher stacking of materials, improved workflow, and more efficient use of their existing facility without costly renovations.

- Increased Productivity: The efficient 6.6 m/min single lifting speed ensures rapid and reliable material movement, reducing downtime and accelerating production cycles. The dependable three-phase power ensures consistent performance even during peak demand.

- Mejora De La Seguridad: Precision control reduces the risk of accidental load swings or collisions, contributing to a safer working environment for operators and personnel. DQCRANES hoists are built with safety features that meet Australian safety guidelines.

- Reliable Performance: Engineered for heavy-duty industrial use, these hoists provide consistent and dependable performance, minimizing maintenance needs and ensuring uninterrupted operations.

- Cost-Effective Solution: By optimizing their existing facility, the client avoided the substantial costs and disruptions associated with expanding or relocating, proving to be a highly cost-effective investment.

Why Australian Clients Chose DQCRANES?

This case study exemplifies DQCRANES’ dedication to providing customized, high-performance lifting solutions. For businesses in Sydney, Melbourne, Brisbane, Perth, Adelaide, and across Australia seeking to overcome challenges of limited overhead space, our low headroom electric hoists are an ideal choice. We understand the unique demands of the Australian industrial landscape and are committed to delivering equipment that not only meets but exceeds expectations for safety, efficiency, and durability.

Our low headroom cranes and hoists are perfect for a variety of applications in Australia, including:

- Manufacturing plants with low ceilings

- Warehouses and distribution centers require maximized storage

- Workshops with overhead obstructions

- Automotive service centers

- Any industrial setting where vertical space is at a premium.

Looking for a customized lifting solution that maximizes your operational space in Australia? Contacto DQCRANES today to discuss your specific requirements.