At the end of March, a customer from Philippines left a message through our website (www.hoistdq.com), inquiring about the 5 ton winch. Then the customer indicated that he would purchase six winches. After communicating with the customer to determine the winch specifications, the two parties signed a purchase contract. The customer then paid 50% of the purchase price as a deposit. At present, all six winches have been produced and are ready to be packed and sent to Southeast Asia.

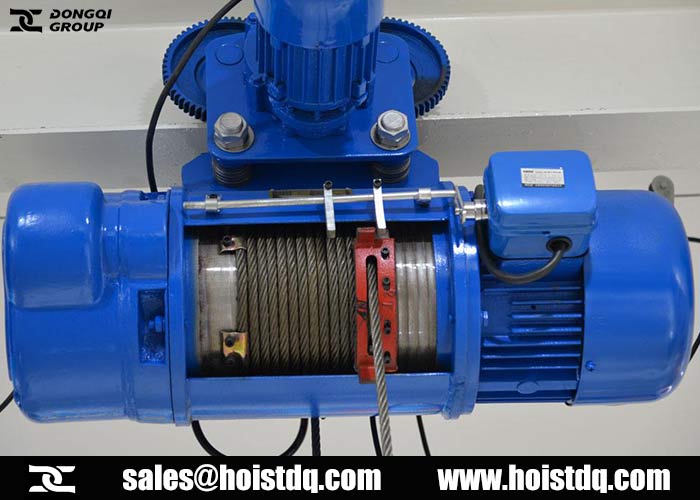

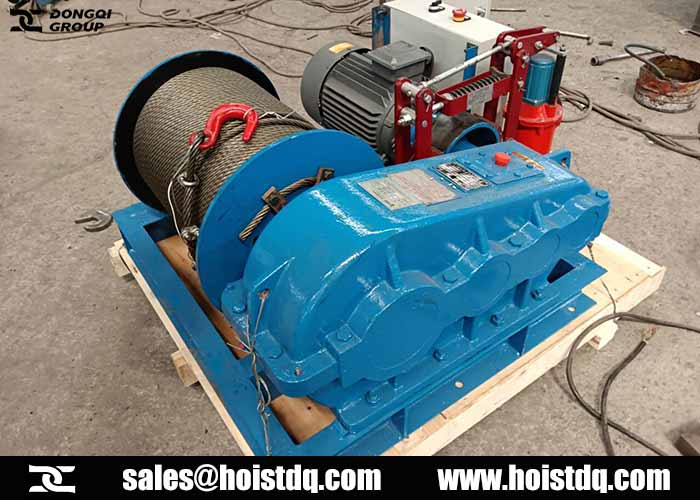

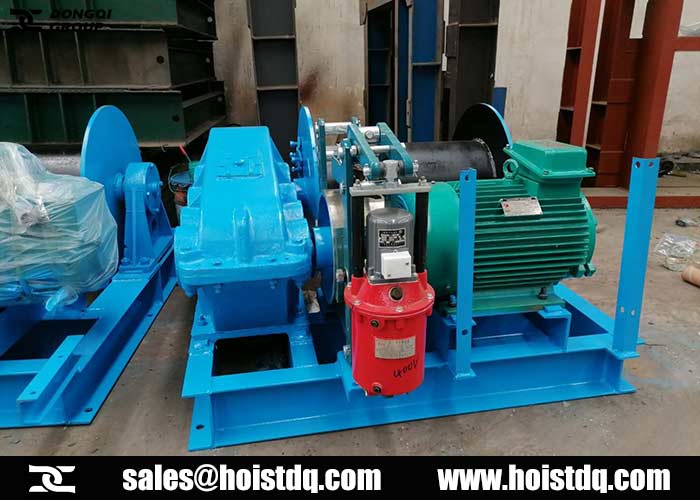

electric winch for sale to Philippines:

- Winch type: JM5 electric lifting winch

- Rope length: 250m

- Application: Vertical lifting

- Lifting speed: 20m/min

- Power supply: 380V/50Hz/3 Phase

- Working conditions: Indoor use, for lifting angular steel.

Note: The winch configuration can also be determined according to customer requirements.

5 ton electric winch production and package:

How to install a winch?

- Set up an operating shed, and ensure that the operator can see the commander and the dragged or lifted objects clearly. During the construction process, the buildings, scaffolding, and on-site stacked materials and components should not affect the driver’s monitoring of the entire process within the operating range. When operating a shed in a hazardous work area, the top should meet the requirements of a protective shed.

- Ensure that the foundation is strong. The hoist should be kept away from the dangerous operation area as far as possible, choose a place with higher terrain and firm soil, and bury the ground anchor with a steel wire rope to lock the hoist base, and pile up the front to prevent the hoist from moving and overturning.

- Pay attention to the direction of the roll. The reel is aligned with the center of the guide pulley. According to regulations, the distance from the reel to the first guide pulley: the grooved reel should be more than 15 times the width of the reel, and the non-slot reel should be more than 20 times the width of the reel to prevent the wire ropes from overlapping and wearing when the reel is running.

How to operate electric winch safely?

- The wire rope on the drum should be arranged neatly. If the wire rope is overlapped or slanted, stop the machine and rearrange it. It is strictly forbidden to pull and step on the wire rope during rotation. The wire rope is not allowed to be fully released, and at least three turns should be retained on the drum.

- The wire rope is not allowed to be knotted or twisted. When the wire is broken more than 10% within a pitch, it should be replaced.

- No one is allowed to cross the wire rope during operation, and the operator is not allowed to leave the wire rope winch after the object is lifted. Objects should be lowered to the ground during rest.

- During operation, the operator and signalman must maintain good visibility with the hoisted object. They should cooperate closely and obey the unified signal command.

- In case of a power outage during operation, the power supply should be cut off and the lifted object should be lowered to the ground.

- Obey the signal of the commander during the work. If the signal is unknown or may cause an accident, the operation should be suspended. It can be continued after the situation is clarified.

- It is inevitable that the steel wire rope will be worn with the machinery during use, so it should be brushed with protective oil at intervals.

- Overload use is strictly prohibited.

- Do not directly hoist high-temperature objects. For objects with edges and corners, add a protective plate.

- The steel wire rope should be checked frequently during use, and it should be scrapped immediately if it reaches the scrap standard.

Get your 5 ton electric winch price!

In order to provide you with an accurate quotation, please kindly contact us and provide the following information:

- What are the uses of your winch? lifting, pulling, anchoring, mooring or towing?

- The environment that your winch will be operating in?

- Your required electric winch specifications, including rated load capacity or pulling force, line speed and drum capacity.

- Single drum or double drum?

- Do you require additional components and features, such as clutch, band brake and rope guide?

- Other special requirements?