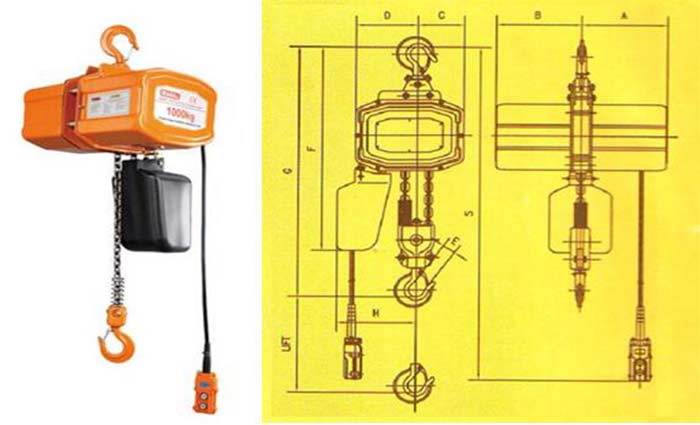

electric hoist & Electric chain hoist

An electric hoist is a lifting equipment, designed to lift, move, and lower loads easily, simply, and safely. Typically, the hoists use wire rope or chain to lift materials. There are different types of hoists, such as electric chain hoist, electric motor hoist, I beam hoist, electric pulley hoist, electric monorail hoist, single speed and double speed electric hoist, fem electric hoist, low headroom hoist, electric hoist, explosion proof electric rope hoist, metallurgical electric hoist, etc.

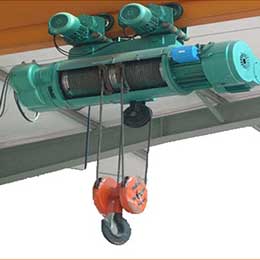

Single gider hoist and Double girder hoist

Advantages of Dongqi’s types of hoists

Electric hoists of the Chinese hoist supplier, Dongqi Hoist has the advantages as follow:

- The various types of hoists are designed with compact structure, small size, and light dead weight.

- The performances of Dongqi electric hoists and electric chain hoists are reliable.

- Various types of hoists have a wide application.

- Easy operation is the one advantage of the Dongqi’s electric hoists.

Applications of Dongqi’s types of hoists

Electric hoists can be applied in various conditions and have different moving ways, which should be selected according to your applications.The various types of hoists have a wide range of application, which can be used in the various applications:

- Factory, storage, wind-power stations, logistics, ports, construction field, and other places or workshops, etc.

- The type of hoists of Dongqi also can be used to handle heavy objects for working or reparation.

- The electric hoists of Dongqi can be used together with monorail electric trolley for material handlings.

Hoist operation safety lists

- Do not exceed the safe load limit of hoist.

- Maintain hoist ropes and chains lubricated.

- Hoist loads up from right over the loads or it may swing when lifting if not centered.

- Place hoists in the highest part of hook area to make sure hook support is in line with hook shank directly.

- Lever operated hoist can be pulled in any direction in a straight line. However, side pulling or lifting increase wear and stress on hoist parts.

- Pushing a loaded hoistPushing a loaded hoist is safer (A). If it must be pulled, use a rope (B)

- To load the lower hook, place loads right in line with the hook shank to make sure load chain in a straight line from hook shank to hook shank.

- Stand clear of load completely.

- Place loads in the hook completely.

- Move hoist controls smoothly to avoid abrupt and jerky movements of loads.

- Make sure the sling and hoisting ropes from slacking before lifting.

- Keep the loads from any loose material, parts, blocking and packing before lifting.

- Make sure all people away from loads before lifting.

Detailed information about electric hoist and electric hoist, please check electric hoist specifications. More Hoist and Crane is at Dongqi Hoist and Crane Product Center.