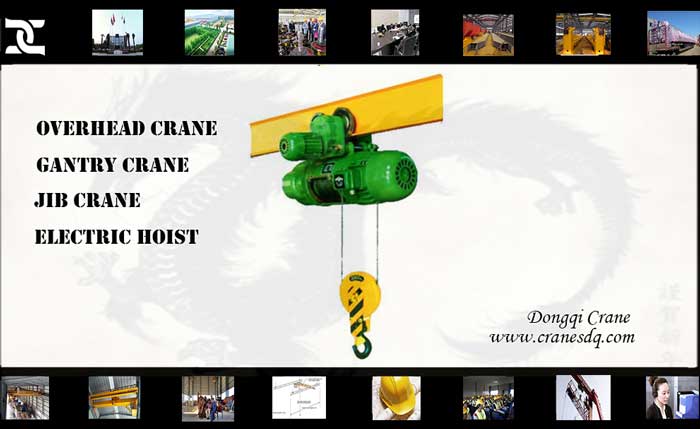

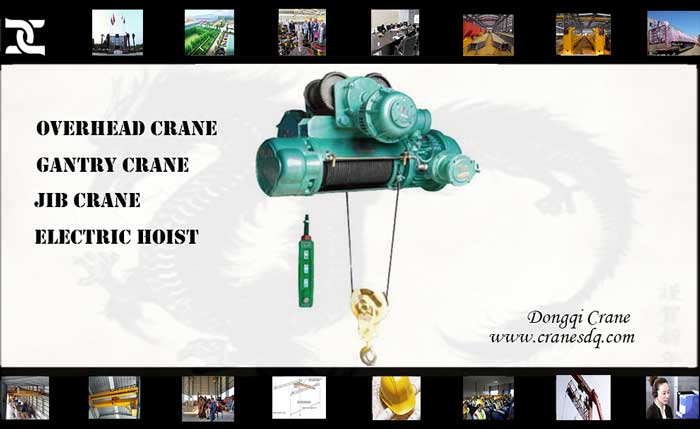

Wire rope electric hoist is the oldest electric hoist and also the most widely used electric hoist. Traditional single-speed electric hoists and double-speed electric hoist have been optimized for many generations and have become the most cost-effective electric hoist on the market. At the same time, in order to meet the special requirements of special working conditions, Yuantai designed and improved the metallurgical hoist dedicated to the metallurgical industry and the explosion-proof electric hoist suitable for flammable and explosive environments.

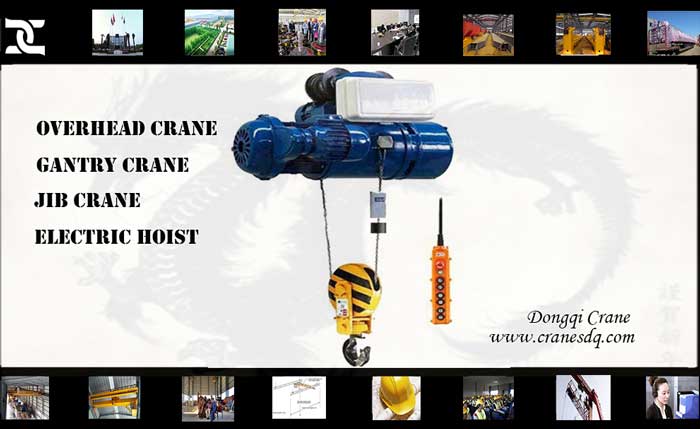

With the gradual integration of domestic and international standards, the market needs higher efficiency, lower energy consumption, and safer lifting equipment. Yuantai Crane timely launched Europ-spec lifting equipment, including ND type European standard electric wire rope hoist and European crane system to meet market demand. European electric wire rope hoist has a more advanced design concept. Compared with traditional electric hoists, it has a modular design, compact structure, low headroom, low noise, low energy consumption, more stable operation, higher efficiency, and maintenance-free characteristic. Once the product was launched, it quickly became popular in the domestic market. Compared with the electric hoist of international brands, it is very cost-effective, and it is deeply loved by foreign customers. It has become one of the main products of our company.

Check the hoists below to find your hoist, if you need help, talk with our online service, you will get a suitable electric hoist quickly.