jib crane for sale | Jib crane Types | Jib crane service

Jib crane is the most economical lifting equipment for short distance material handling. Jib crane is a type of crane where a horizontal jib or boom, with a hoist as the lifting system is fixed on a wall or a floor-mounted pillar. Jib cranes can be classified into pillar jib crane, wall-mounted jib crane and pillar jib cranes, etc. Jib cranes are used to improve material handling efficiency and lower working.

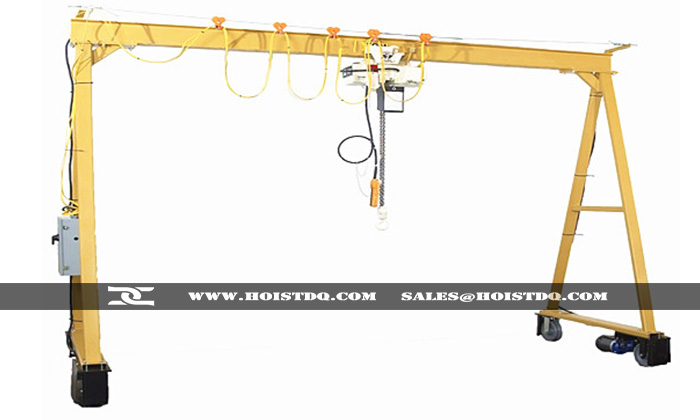

most popular jib crane

Why choose Dongqi Hoist and Crane as your jib crane supplier?

Why to choose Dongqi Hoist and Crane as your jib crane supplier? See the following reasons:

DONGQI CRANE Emphasizes on Safety.

Human and process safety is what DONGQI CRANE emphasis. To prevent crane accidents and injuries and damage, standards, regulation and guidelines should be fully, thoroughly and systematically carried out because they define standardized and distinct safety concepts for manufacturers and operator, inspection and maintenance at national and international levels.

DONGQI CRANE Provides Quality Products.

DONGQI CRANE now owns top level machine parts processing production line. Our crane production lines are at your services, which can produce CE certified products for you. Each production procedures of DONGQI CRANE is strictly carried out according related standards and supervised by our quality control staff. The quality of each product can be guaranteed. The 5-10 years warranty can be given according to the designing requirements of customers.

Price of DONGQI CRANE is unbeatable.

Cost-effective is one of the well-known features of Chinese products. So do Chinese cranes. Do you know why Chinese cranes are so cost-effective? Now let’s uncover the secrets of why Chinese crane machines are so cost-effective:

- Domestic demand promotes technology development on Chinese material handling equipment in China.

- Beneficial policy support makes Chinese materials handling equipment more competitive.

- Fierce competition makes the price of Chinese material handling equipment more inviting.

- Direct sale makes Chinese materials handling equipment more cost-effective. As one of Chinese crane manufactures, DONGQI CRANE can promise you to provide the quality products with the unbeatable price.

DONGQI CRANE serves you with Heart-and-soul.

Once you choose DONGQI CRANE, you will have over 3,600 people at your service, which includes 500 are technicians, and over 70 are senior engineers, also an excellent overseas team 36 people, to give English, Arabic, Spanish, Russian, Korean, etc. language services.

We can provide a series of crane services including but not limited to Crane project design, Crane Installation , Lifetime Maintenance , Crane operator Training, 24/7 Technical support , Crane Modernization ,Crane Parts supplying , etc.

DONGQI CRANE is Trustworthy.

As one of the top crane manufacturers in china, DONGQI CRANE is famous in the crane industry. And also it is well-known for its outstanding annul output value, the comprehensive annual output value of DONGQI CRANE has been increased to 15 billion RMB in 2014, which make DONGQI CRANE well-known by the people outside of crane industry.

DONGQI CRANE output value

The brand of DONGQI CRANE is highly recognized and accepted. The annual crane production capacity of DONGQI CRANE is up to 10,000 suits/sets, which are distributed throughout the Southeast Asia, East Europe, Middle East, Africa and other areas, and other etc.

More on Hoist and Crane is at Dongqi Hoist and Crane Product Center.