wire rope hoist supplied by DQCRANES is especially popular in production environments because it can perform lifts at a faster speed, lift to higher heights, and can be rated for more severe duty cycle classifications when compared to chain hoists. They are also able to dissipate heat from extended usage with higher duty cycles in more demanding or severe lifting applications.

Types of Wire Rope Hoists for Sale:

- Single speed CD1 wire rope hoist

- Double speed MD1 wire rope hoist

- European standard wire rope hoist

- Explosion-proof wire rope hoist

- Metallurgical wire rope hoist

- Low headroom wire rope hoist

Advantages of Wire Rope Hoists:

- Offers very fast lifting speeds.

- Can be rated to severe duty classifications.

- Dominates the market at 10-tons and above.

- Quieter and smoother lifting operation.

Contact Us if you need wire rope hoists!

Additional Features and Benefits Include:

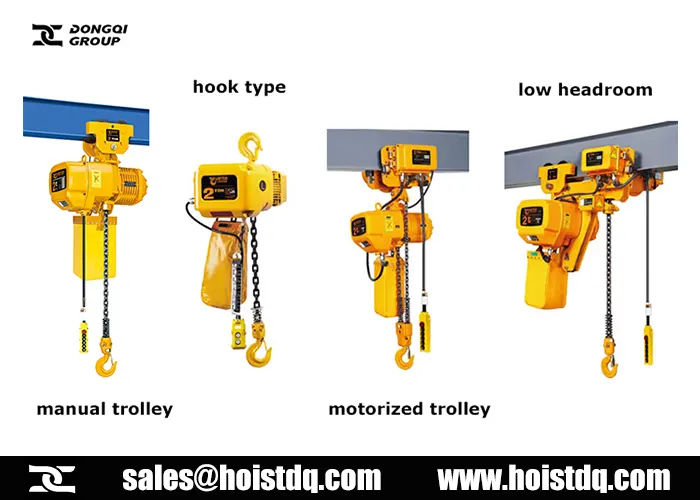

- Fixed or Motorized Trolley.

- Easily accessible control enclosure facilitates maintenance.

- A.C. motor brake for smooth braking action.

- High torque, heavy-duty hoist motor for smooth hoisting action.

- Block operated upper limit stop to limit upward hook travel.

- Convenient one-handed pushbutton control for easy operation of all motions.

- Push-button cable with built in strain reliever cable as used on single speed hoist applications (All others use a separate steel strain reliever cable.)

- Improved plow steel pre-formed cable for maximum strength and life.

- Full-swiveling, heat-treated forged an existing facility, reducing or steel hook with spring loaded latch.

- Shrouded lower block to help prevent pinched fingers.

- Alloy aluminum gear case and cover is lightweight yet rugged.

- Oil level plug permits easy inspection of oil level.

- Anti-friction bearings throughout for a long lasting hoist drive train

- Positive action mechanical load lowering control brake, also acts as a part of the hoist holding brake system

- Deep grooved, large diameter rope drum helps prevent rope mounting from an overhead structure, or with any of our overwrap for longer wire rope life.

- Heavy welded steel frame ensures precise fit for long hoisting machinery life.

Above may show optional features and accessories not included on standard models. Contact us with the product catalog for more information.

Wire Rope Hoist Operation Instruction:

- The hoist should be operated by a special-assigned person, all the operation person must be trained and pass the job examination before work.

- Check the safety performance of the equipment before lifting work, confirm if the machine, wire rope, hook is fixed firmly, if the turning parts are flexible, if the power supply, the ground connection, button, travel switch is in good condition and sensitive, if the limit switch is in good condition, if the left and right track, pulley, drum, brake is installed well. There must be no damage, the motor and reduce should have no abnormality, the wedge should be firmly installed.

- Don’t operate while finding the wire rope is bent, transformed, worn, etc.

- Don’t lift materials before adjusting the stop piece of the limit switch.

- Make sure the braking glide is adjusted with nominal load.

- It’s not allowed to have person under the lifted materials.

- It’s not allowed to lift person with the materials, never use hoist to load person as an elevator.

- The hook can not be lifted to the level above the hoist.

- During use, it’s forbidden to work overload or exceed the rated switching times (120 times)and work in unallowed environment.

- Reduce the traveling speed of the monorail electric hoist while it is in the turning point of the rail or near the end of the rail.

- Don’t hung the heavy material in the air during work. The hook is not allowed to lift materials while it is in the condition of swing.

- The hoist must be right above the materials before lifting, it’s not allowed to lift in the condition that the hook is not vertically above the materials.

- Limit switch is not allowed to be used as travel switch.

- Don’t lift the materials connected with the ground.

- Excessive inching operation is not allowed.

- There must be specially assigned person to check the hoist regularly, take actions timely to cut off the power supply and make a record when there are problems.

- Make sure there’s enough clean lubrication oil without dirt and impurity during use.

- Use scrub brush or small wood piece to add oil to the wire rope, using hands is not allowed.

- Cut off the power supply before maintenance and checking, checking and maintenance must

- be done in the condition of no-load.

- Don’t hung the heavy materials in the air while the hoist is not working, to avoid the permanent

- deformation of the machine parts, which may lead to personal and property loss.

- After finishing work, cut off the power supply from the main switch.

Choose a Right Wire Rope Hoist for Your Job!

Before you choose the right wire rope hoist, keep these three considerations in mind so you can find the best equipment for your needs.

Wire rope hoists are often preferred over electric chain hoists for lifting heavier loads because they offer faster lifting speeds and lower headroom. Our wire rope hoists are very popular all around the world, are made to the highest professional standards. With capacities ranging from 500kg to 65 tons.

Welcome to email us at sales@hoistdq.com and one of our knowledgeable representatives will gladly assist you with any questions or concerns.