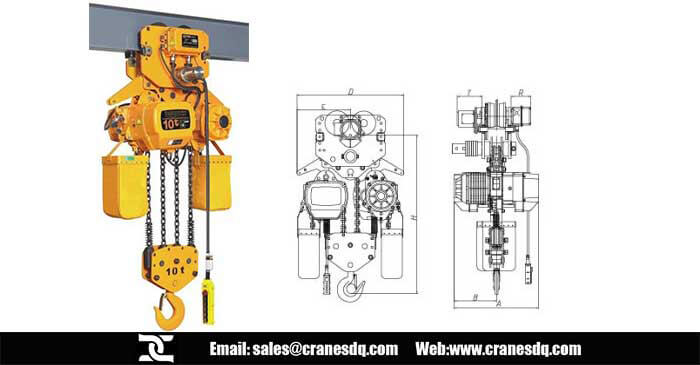

Crane hook part

Crane hook part for your overhead crane, gantry crane, and other types of lifting equipment is for sale. Type of Crane hook parts with different Crane hook part dimensions are available. Crane hook part design service is also available. Check types of Crane hook parts now and get your Crane hook part designed.

Crane lifting Crane hook part is a common device for grabbing and lifting loads used by a hoist or crane. The lifting Crane hook part is usually equipped with safety latch to ensure the wire rope sling, chain or rope in the proper place of Crane hook part and ensure the safety. With one or more built-in pulleys, the Crane hook part group can amplify the lifting force.

Application of Crane hook part group

Due to the characteristics of simple manufacture and strong usability, Crane hook part group is used widely to handle materials. As the most widely used loads handling devices, Crane hook part groups are usually used with hoist or crane machinery for handling materials in various applications in different industries.

Crane hook part

Crane hook part

Types of hook

According to different standards, Crane hook parts can be classified into different types, the single and double hook, the forging and laminated hook, closed and semi-closed hook, and other hooks, such as, electric rotary hook, etc. according to the different features, these types of Crane hook parts are widely used in different applications.

1) On the shape of hooks

Crane hook parts can be classified in to single hook, C type hook, and double hook, etc.

Different shapes of Crane hook parts

Different shapes of Crane hook parts

Single Crane hook part is usually used for handling loads under the weight of 75 tons, with the feature of simple manufacturing and convenient to use, etc.

Due to the good bearing capability, the double Crane hook part is widely used for heavy loads handling.

2) On manufacturing methods

According to the produciton methods, Crane hook parts can be classified into forging crabe hook and Laminated Crane hook part.

Forging Crane hook part

Forging Crane hook part

The forging Crane hook part is made of high quality low carbon steel or low carboon alloy steel, such as, 20 high-quality low carbon steel, 16Mn,20MnSi,36MnSi, which is annealed after being forged.

The forging hook is simple to be manfactured and is easy to be operated however its stress condition is not as good as laminated hook. Therefore, the froging hook is usually used for handling loads below 80 tons. And double hooks will be adopted when come into handling heavey loads.

Laminated Crane hook part

Laminated Crane hook part is riveted through several pieces of steel plates. The laminated hook provides high safety for when one individual plate has flaws, the whole hook still can work without being damaged. With the features of high safety and large dead weight, laminated hook is usually used on large lifting capacity cranes, such as, steel ladle cranes, etc.

Laminated hooks also can be classified into single laminated hooks and double laminated hooks.

Laminated Crane hook parts

Laminated Crane hook parts

3) Closed and semi-closed Crane hook parts

Closed and semi-closed Crane hook parts

4) Electric rotary Crane hook part

Electric Crane hook part

5) Other types of Crane hook parts

Crane hook design service

As a well knonwn crane parts manufactuer and supplier, Dongqi Hoist and Crane is able to produce and design types of Crane hook parts for crane manfuactuers and for crane end users. With powerful crane designing team, Dongqi hoist and crane is able to provide Crane hook part design services to produce types of sepcalized Crane hook parts. If you overhead crane, gantry crane, or other types of cranes need unique Crane hook parts, please feel free to contact us.

Crane hook part maintenance

(1)Dismount all the Crane hook part head, shaft, beam, pulley block, bearings, check the condition, clean and lubricate if necessary.

(2)Check the wear condition of the dangerous cross section.

(3)Test the Crane hook part.

(4)Check the condition of Crane hook part plate.

- Crack is not allowed on the Crane hook part, beam and pulley block. The screw cannot be loosened. The bearing should be in good condition. Rotate the pulley, if find out the cutter mark or crack on the tool escape, please change it.

- If the wear of the dangerous cross section is more than 10% compare to the original height, please change it.

- After the repairing, testing and checking is necessary for the Crane hook part. Hanging the 1.25 maltaple weight compare to lifting capacity in 10 minutes, the mouth of Crane hook part should be opened less than 0.25% compare to the original size. After unloading the deformation and crack are not allowed.

- After riveting for the Crane hook part plate, the gap between the plates should be less than 0.3 mm.