electric hoist and electric winch, which do you choose? Electric hoist and electric winch look similar, how to choose for your application? Check the electric hoist and electric winch comparison.

An electric winch is designed to pull a heavy load horizontally over a slightly inclined or level surface, and an electric hoist is designed to lift a load vertically over steeper inclines greater than 45 degrees. Using a winch or hoist can make heavy lifting tasks easier, however for your safety, it’s important to make sure you are choosing the right equipment for the job.

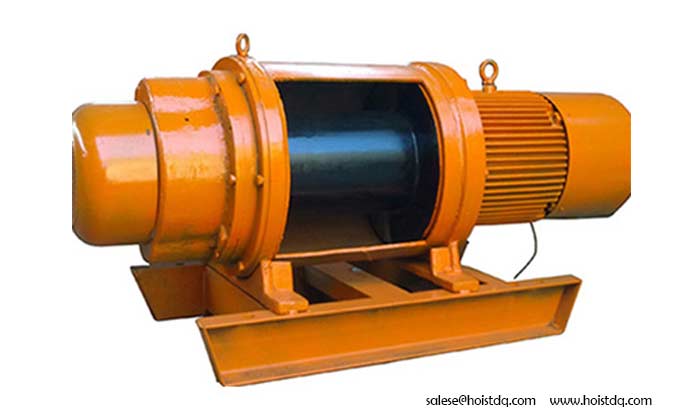

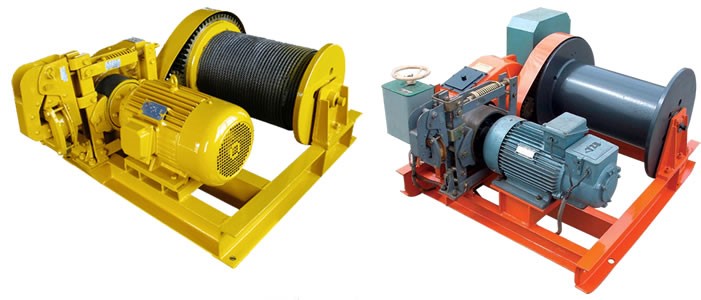

How Electric Winches Work

Electric Winches are devices used to wind a cable or a rope in or out, so that the resulting tension pulls an object. The Electric Winch drum may be powered manually or by air, electricity, or hydraulics. Most Electric Winch drums are made of fabricated steel and are designed for a specific load capacity. A simple Electric Winch, such as a manual Electric Winch, consists of a rope or cable wound around a drum or barrel. More complex industrial Electric Winches, like electric Electric Winches, are used to tow automobiles, boats or to help move pieces of heavy equipment.

Choosing the Right Electric Winch

Electric Winches are rated by a maximum pulling load or line pull. This is determined by the maximum load an electric Winch can pull with only the bottom layer of rope on the drum. As the layers of wire rope increase, the line pull typically decreases by approximately 10 percent per layer. The size of Electric Winch you need for a job depends on many factors including the object’s weight, if the item has wheels, and whether you’ll be pulling it across a flat or sloped surface. A simple formula to determine the minimum size of Electric Winch you’ll need is to multiply the gross weight of the heaviest object you plan to pull by 1.5. For example, if you plan to pull a 1,000-pound object, you’ll need an electric Winch with a minimum of 1,500 pounds of line pull. It’s important to keep in mind that there numerous variables associated with Electric Winching, so it is best to consult with the manufacturer to verify the proper Electric Winch size for your intended application.

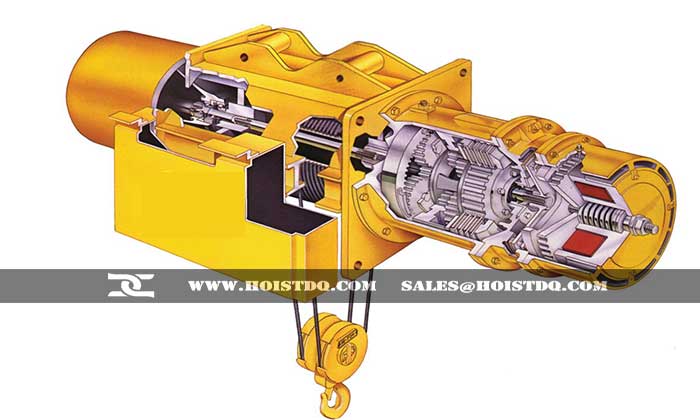

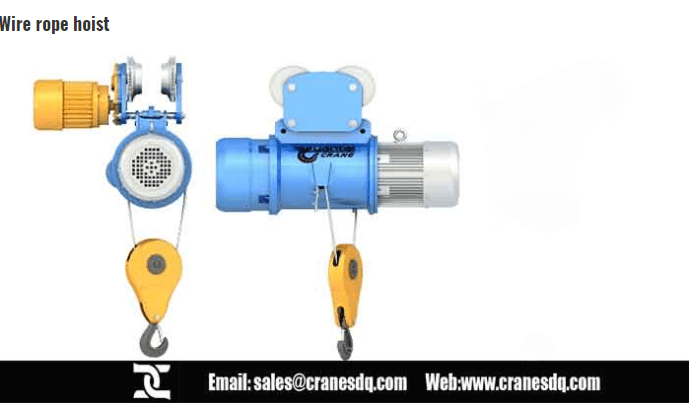

How Electric Hoists Work

Lifting heavy objects, like an engine block or construction material may seem like a perfect job for an electric Winch, but that’s not the case. Instead, for jobs that require you to lift or lower a load, you should use an Electric Hoist. Electric Hoists are typically made with chain or wire rope, and can be operated manually or by powered motors. Powered Electric Hoists include all those that are driven by electric, hydraulic, or pneumatic motors. Manual Electric Hoists include all those that are ratcheted, levered or hand cranked. Electric chain Electric Hoists are ideal for mechanics and machine shops because they can be plugged into any standard electrical outlet. Air chain Electric Hoists are recommended for lifting heavy materials in flammable, dusty or dirty environments.

Choosing the Right Electric Hoist

Electric Hoists are rated by the maximum amount of time they can be used in one hour, or their maximum on time in addition to the maximum number of starts per hour. These factors determine the Electric Hoist duty cycle rating ranging from H2 (light duty) to H4 (industry standard). An H2 light duty Electric Hoist means that it will run for no more than 15% of the work period with a maximum of 75 starts/stops per hour. An electric Hoist with a rating of H4 means that it is rated to run approaching 50% of the work period and can handle a maximum of 300 starts/stops per hour. One of the most common problems with Electric Hoists is when they are used beyond their intended duty cycle rating. Before using an electric Hoist, consider the task and match the duty cycle rating accordingly. If your Electric Hoist is undersized, it can cause premature damage to the Electric Hoist. Another important factor to consider is the environment in which the Electric Hoist will be used because duty cycle ratings work within certain temperature ranges.

Using an electric Winch as an electric Hoist

One major distinguishing factor between an electric Winch and an electric Hoist is the breaking system. The majority of off-road Electric Winches are made with dynamic brakes in which the gear system is designed to automatically hold the load. Dynamic brakes use the gears in the Electric Winch for resistance making it unstable for suspended loads. For this reason, if you were to try to use an electric Winch as an electric Hoist, the load could slip or the gears could strip resulting in a very hazardous situation.

Electric Hoists use mechanical braking systems that feature a physical brake which locks the suspended material so there is no line to bleed. Electric Hoists also do not have a free spool mechanism. This makes Electric Hoists the safer option for lifting materials, since there is a reduced risk of the load slipping off. Electric Hoists are also equipped with a load-limiting switch to prevent it from trying to lift more than its designed capacity.

Some Electric Winches are specially manufactured to double as an Electric Hoist. In order for an Electric Winch to be used as an Electric Hoist, it must have a locking brake and no free spool mechanism, or you must be able to remove or disable the free spool mechanism. You should never use an Electric Winch as an Electric Hoist unless the manufacturer clearly states the Electric Winch is approved to use as an Electric Hoist.

Electric Hoist and Electric Winch Maintenance Tips

Due to the potential risk for injury, Electric Hoists and Electric Winches must be properly maintained. It’s important to follow your manufacturer’s maintenance instructions in addition to these general guidelines for safe operation.

- Inspect your Electric Winch before and after each time you use it. If the wire rope has become damaged, frayed or kinked, it’s important to replace it right away.

- Keep the Electric Winch, wire rope and remote control clean. If necessary, unwind the Electric Winch completely and use a clean rag to remove any dirt and debris.

- If using a vehicle-mounted Electric Winch, be sure to check and maintain your vehicle battery and its cables. Operating the Electric Winch for longer periods of time puts extra strain on your battery.

- Ensure your Electric Hoist remains in proper working condition through regular maintenance. Conduct routine load testing to ensure you know just how many pounds the Electric Hoist can handle.

- Regularly inspect your chain electric hoist and lubricate according to the manufacturer’s instructions.

Electric hoist and electric winch, which do you choose? Contact us for free consultation to get your custom electric hoist or electric winch now.