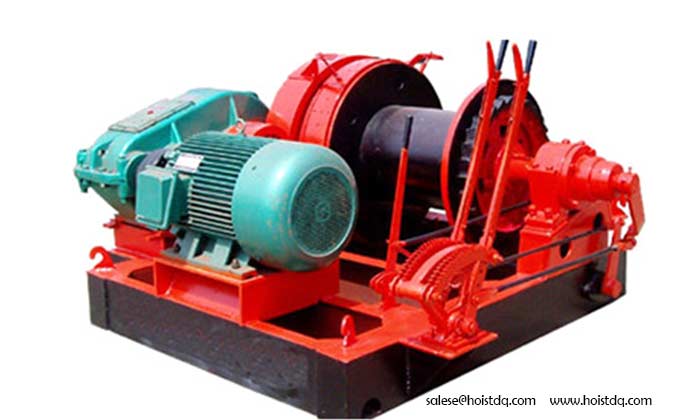

electric winch

Electric winch overview

Electric winches are most commonly used to pull an automobile, boat, crane, truck, or other piece of equipment from a problematic area. If a car goes off the road and down into a ravine, for example, trucks with these types of winches are used to hook the car and pull it back to the road. They can also be used to tug boats to safety. There have even been rare instances in which they have helped save large animals from tricky holes and pits.

Electric winches come in different shapes and sizes. Typically, they include a two-speed engine. A cable is attached to a spool, which is attached to the motor. A gear lever turns the spool in order to release the cable.

Once the cables of an electric winch are extended to the vehicle or object in need of towing, the gear levers are pushed in the opposite direction of the object. This causes the spool to wind up. As the spool winds, the cables are pulled back in. This causes the object to be pulled safely to where it belongs.

Electric winches are usually capable of handling loads of 500 pounds (267 kg)to two tons. The cables and motors of these winches are created specifically to to handle different weight loads. Winches capable of handling larger load capacities are more expensive. Those capable of handling 12,000-pound (5,448 kg) loads, for example, cost well in excess of 700 US Dollars (USD). A typical 9,000-pound (4,086 kg) winch costs between 300 and 600 USD.

The standard length of the cables on an electric winch is 100 feet (30.5 m). These winches also come standard with an automatic brake and a handheld remote control. They can deliver engine performance of one-third horsepower to over 50 horsepower. They can be easily installed to the back of a truck, boat, or solid surface. When buying electric winches, however, it is important to research each product and to read consumer reviews because many models make promises on which they cannot deliver.

The largest electric winch in the world is rigged to a platform in a deepwater construction vessel called the Balder, which can handle loads of 275 metric tons. The Balder can hold 350 workers and is used to save sinking oilrigs, to assist in the installation of underwater oil lines, and to install oil platforms.

Comparisons of electric winch and Hydraulic Winches

Electric Winches

An electric winch is exactly as its name would suggest: it is electrically powered by a vehicle’s battery, and as a result its duty cycle is limited by the amount of juice in your battery. Oftentimes, it is wise to run your engine while operating an electric winch to prevent your battery from fully draining.

Hydraulic Winches

A hydraulic winch is powered by a vehicle’s power steering pump. What this means is that they are capable of an extended, seemingly endless duty cycle for longer pulls and a persistent flow of pulling power.

It may seem like hydraulic winches are clearly superior to electric winches. This is true from a conceptual standpoint, but in practice, each has its benefits and detriments.

Essentially, there’s no wrong decision either way. But what this guide boils down to is the fact that electric winches are far more universal. There are many more models of electric winches available, and they can be installed on just about any vehicle with universal mounting kits. Additionally, they are much easier to install or remove, and often include more choices in slick features than their hydraulic counterparts.

Winching Technique

For as much that can be said of the particular features and specifications of electric winches, just as much attention should be paid to proper utilization and winching technique.

While seemingly a simple premise in itself, there’s actually a lot more to winching than attaching the cable to a fixed point and letting it rip. In fact, knowing how to effectively utilize your winch can make a significant impact on its performance.

Factor in the fact that electric winches are allotted a limited amount of time to complete a pull before it saps your battery or begins overheating, and proper winching technique suddenly becomes that much more important.

Here are technical factors to keep in mind for electric winch selection and operation:

Winch Capacity, Part 1:

Hopefully by now, off road and 4×4 enthusiasts have all but eliminated the rookie misconception that the necessary winch capacity is directly proportional to a vehicle’s weight. But in case there is still any confusion regarding this matter, let’s put it bluntly.

Plain and simple, your winch capacity should be 1.5 times your gross vehicle weight. In other words, take your vehicle’s weight, multiply it by 1.5, and that resulting number should be your minimum winch capacity.

For instance, a vehicle that weighs 5,000 lbs would require a winch with a minimum capacity of 7,500 lbs.

Winch Capacity, Part 2:

When shopping for an electric winch, it’s easy to get confused by all the ratings, specs, and other technical information; in particular, winch capacity.

Fact is, even if an electric winch is rated 10,000 lbs, it won’t always pull at 10,000 lbs. The way the ratings systems works is that each winch is given a designated capacity based upon its pulling strength with one layer of winch cable.

In other words, an electric winch has the most pulling power when 1-2 complete layers of winch cable are wound around the winch drum due to a lower gear ratio. As a winch continues to wrap more layers of cable around the drum the pulling power decreases.

Effective Winch Line Management

While you may want just one layer of winch cable around the drum when you begin a pull, the problem is that you may have to spool out a considerable amount of cable depending on how much you have on the drum, which can get snagged, damaged, or bunched up on the drum as you pull.

For this reason, it’s important not to carry too much winch cable. 100 feet is usually a standard length and some spare extension cable can help with pulls over longer distances.

In terms of the act of winching itself, make sure to feed the winch rope straight through the fairlead so that it will wrap smoothly and linearly around the drum. Feeding from an angle will cause the rope to layer unevenly, which could affect your winch’s performance.

Safety First:

No matter what your circumstances, safety is your first priority during any recovery or utility option. Common sense rules like never using an electric winch to hoist or pull people usually apply. Here are some basic safety tips that should always be followed when operating a winch:

• Always use gloves when operating a winch, especially when using wire rope. Individual wire strands can sometimes break, which can lacerate unprotected flesh.

• Keep your hands clear of the winch drum during operation.

• If using a wire rope, spread a blanket or towel or some other object on the rope. If a wire rope snaps, the stored kinetic energy can create a whipping effect. Placing something on the cable will dampen this in the event of rope breakage.

More information, please check Dongqi electric winch.