- Project: Luxury Overwater Villa Resort, Maldives

- Challenge: Lifting heavy construction materials (steel beams, pre-cast slabs, generators) across scattered islands with limited infrastructure, high humidity, and corrosive saltwater exposure.

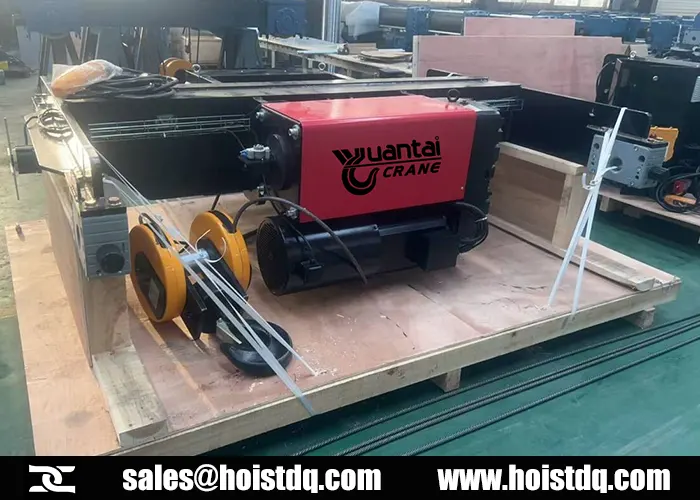

- Solution: DQCRANES 10-Ton electric chain hoist

Electric Chain hoist for sale Maldives

- Lifting Capacity: 10 Ton

- Lifting Height: 14 Meters

- Lifting Speed: 2.7 m/min

- Trolley Type: Motorized trolley traveling with 11 m/min

- Power Supply: 380V/50Hz/3-phase

- Control: Pendant control

- Special Features: Tropicalized Protection (IP65), Saltwater-Resistant Coating, Low-Maintenance Design

This electric chain hoist with motorized trolley to Maldives is designed for smooth, quiet operation and optimal performance in outdoor marine environments.

Design Features & Benefits

Built for Salt & Sun:

Standard electric hoists fail fast in the Maldives. Our 10 ton electric hoist features marine-grade corrosion protection and an IP65 rating – essential for resisting relentless salt spray, high humidity, and intense UV exposure.

Precision & Power for Island Logistics:

The 10-ton capacity effortlessly handled bulky resort components. The 2.7m/min lifting speed provided optimal control for delicate positioning over water and constrained worksites, while the 14m lifting height accommodated multi-story villa construction.

Reliability Where It Matters Most:

Remote islands demand dependable equipment. Our hoist’s robust chain mechanism and sealed electrical components ensure minimal downtime and low maintenance, critical when spare parts aren’t readily available.

Seamless Integration:

The 10 ton hoist was easily mounted onto the project’s custom gantry system, becoming the workhorse for daily material handling – from dock deliveries to final installation points.

Why the Maldives Resort Chose DQCRANES?

The client required reliable, corrosion-resistant lifting solutions for their island-based construction. DQCRANES stood out for:

- Customized lifting solutions tailored to tropical construction sites

- Fast production and delivery timelines to meet project schedules

- Proven durability and safety standards in harsh environments

- Remote support and technical guidance

Delivery & Installation

Despite the location challenges, DQCRANES arranged fast sea freight to Malé and assisted with on-site hoist installation through a local contractor. The electric trolley chain hoist is now fully operational, streamlining heavy lifting for the resort’s structural assembly phase.

Solving Construction Challenges

Limited Space: The compact electric chain hoist design maximizes efficiency on small, crowded island construction sites.

Harsh Climate: Tropicalization ensured smooth operation despite 90 %+ humidity and frequent sea spray.

Tight Timelines: Reliable performance kept the demanding luxury resort construction schedule on track.

Client Feedback

“DQCRANES understood our specific needs – the saltwater resistance was non-negotiable. Their 10-ton hoist performed flawlessly daily, even during monsoon season.” – Project Manager, Maldives Resort Development

10 ton Electric Chain Hoist Price in Maldives

Typical Price Range

Basic models: USD 4,500 – 7,000

Mid-range with enhanced features: USD 7,000 – 9,500

High-end or customized hoists (marine-grade, explosion-proof, etc.): USD 10,000 – 13,000+

Factors Affecting the Price in the Maldives

- Lifting Capacity (250kg to 50, 000kg)

- Lifting Height (3m to 12m, Customized)

- Lifting Speed (Single/Double Speed)

- Control Type (Pendant control vs. remote control)

- Power Supply Requirements

- Hoist Mounting Style (Fixed Type, Trolley Type, and Low Headroom Type)

- Application and Working Environment

- Installation & Support Services

Installation of an Electric Chain Hoist in Maldives

Site Preparation

- Ensure that the supporting structure or beam can handle at least 125% of the rated load.

- Confirm proper power supply (typically 3-phase, 380V or 415V in the Maldives).

- Verify clearance height for the hoist and chain bag.

Mounting the Hoist

- Install the hoist on a beam trolley (manual or motorized, depending on application).

- Align the trolley and hoist to ensure smooth horizontal movement.

Electrical Connections

- Connect to the main power panel using proper circuit breakers and grounding.

- Connect the pendant or the remote control unit.

- Ensure weatherproof wiring and cable routing for coastal protection.

Testing & Calibration

- Test all motions: lifting, lowering, trolley movement (if applicable).

- Set the upper and lower limit switches.

- Check lifting speed and ensure the chain is properly lubricated and untwisted.

Training & Handover

- Train local staff on safe operation and maintenance.

- Provide a load test certificate (usually done at 125% capacity).

- Hand over technical documents and warranty terms.

FAQs: Electric Chain Hoists in Maldives

Need an Electric Chain Hoist in the Maldives?

Whether you’re building a resort, port, or industrial facility, DQCRANES delivers premium electric hoists and lifting equipment across the Maldives and other island nations. Contact us today for a free quote and professional consultation.