In today’s fast-paced manufacturing industry, assembly lines require efficient and reliable material handling solutions. One of the most common solutions is the monorail hoist. Today we’d like to discuss a detailed case of DQCRANES designing a European standard 3 ton monorail hoist for assembly lines in Indonesia, hope can give you some reference.

Client’s Background

Our client is a leading manufacturer of automotive parts in Indonesia. They have been in the industry for over two decades and have established themselves as a trusted supplier to major automotive companies in the region. With the increasing demand for their products, they decided to expand their production capacity by setting up a new assembly line.

Client’s Requirement

The client’s new assembly line required a material handling solution that could efficiently move heavy parts and components along the production line. The solution needed to be safe, reliable, and easy to operate. The client also required the solution to be compliant with European safety and quality standards.

Our Monorail Hoist Design Solution

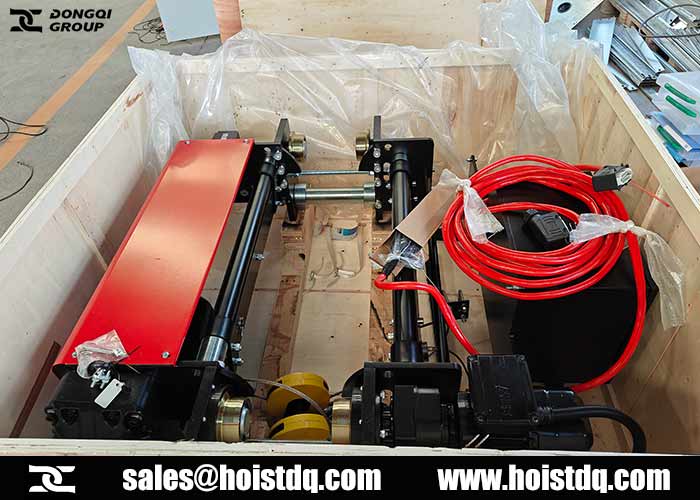

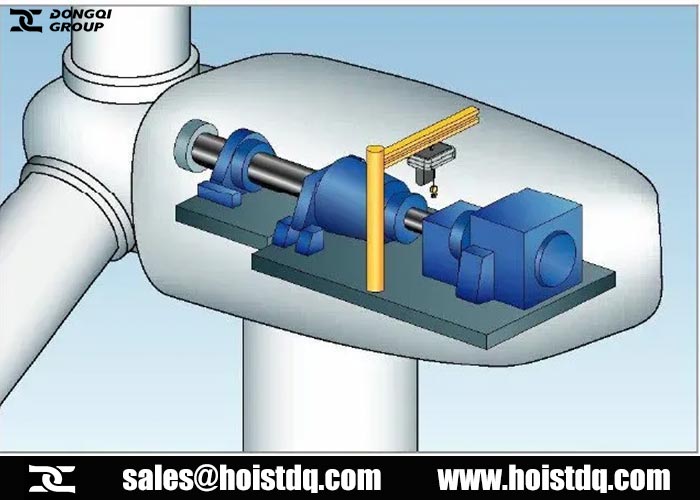

After analyzing the client’s requirements and site conditions, our team of engineers proposed a European standard 3 ton monorail hoist. The 3 ton electric hoist was designed to run on a single girder monorail track system that would be installed along the production line. By leveraging cutting-edge technology, we ensure precise, synchronized lifting, helping to streamline assembly line processes.

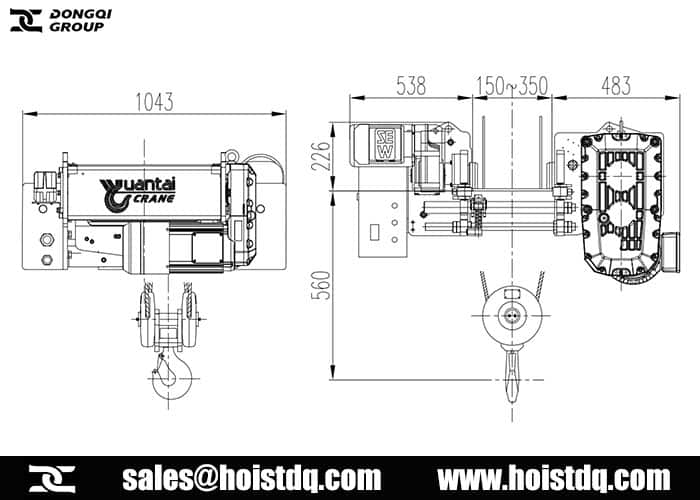

Technical Parameters

- Capacity: 3 tons

- Lift height: 10 meters

- Hoist lifting speed: 0.8/5.0 m/min

- Trolley speed: 2.0~20 m/min STEPLESS

- Lifting power: 0.55/3.6 kW

- Trolley motor power: 0.25 kW

- Power supply: 380V/3P/50Hz

- Lifting/Trolley group: FEM 2m (M5)

- Control method: Pendent control

- Working site: Indoor

Design Details

The European standard monorail hoist is designed to meet the highest safety standards. It is made of high-quality materials that can withstand heavy loads and harsh environments. The hoist is designed to be compact, allowing it to fit into tight spaces. It is also lightweight, making it easy to install and move around.

The hoist’s lifting mechanism is powered by an electric motor that provides smooth and precise movement. The motor is designed to be energy-efficient, reducing the hoist’s operating costs. The hoist also features a brake system that provides additional safety, ensuring that the load remains stationary when the hoist is not in use.

The European standard electric monorail hoist is designed to be flexible, allowing it to adapt to different lifting requirements. It can be customized with different lifting capacities, lifting speeds, and lifting heights. This makes it suitable for a wide range of applications, from small workshops to large industrial facilities.

Design Features

The European standard monorail hoist system comes with several features that make it easy to operate and maintain. These include:

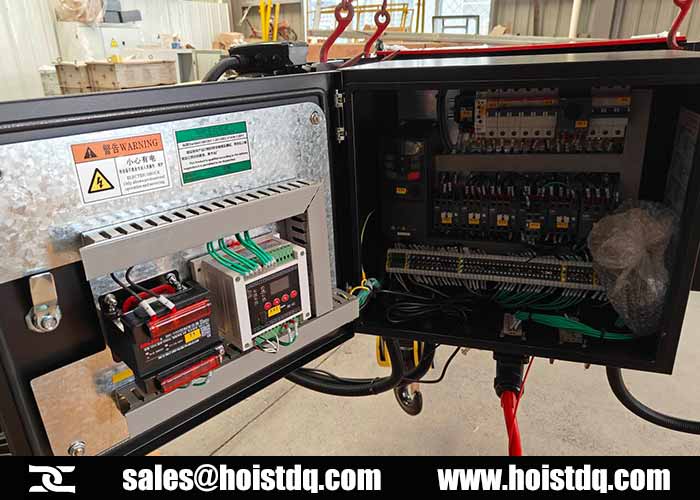

- Load Control System: The hoist features a load control system that ensures the load is lifted and lowered at a safe speed. This prevents the load from swinging or dropping, reducing the risk of accidents.

- Control Pendant: The pendant control is ergonomically designed, making it easy to operate. It features buttons for lifting, lowering, and stopping the hoist. It also includes an emergency stop button for added safety.

- Overload Protection: The monorail wire rope hoist features an overload protection system that prevents the hoist from lifting loads beyond its capacity. This protects the hoist from damage and ensures the safety of the operator.

- Maintenance-Friendly: The European standard monorail hoist is designed to be easy to maintain, with minimal downtime. It features easily accessible components that can be quickly replaced if necessary.

- Durability: The European standard monorail hoist is built to last, with a robust design that can withstand heavy use. It is also resistant to corrosion and other environmental factors that can affect its performance.

Why Choose European Standard Monorail Hoist?

- Improved efficiency: Simultaneous lift capabilities reduce downtime and allow for faster assembly line material handling, optimizing productivity.

- Improved worker safety: Our hoists’ smart safety features protect workers from potential accidents, ensuring peace of mind and complying with international safety standards.

- Long Life and High Reliability: By using quality materials and superior engineering, our cranes offer exceptional reliability and longevity, minimizing maintenance costs.

- Compliance with European standards: Because our hoists comply with European safety and functionality standards, businesses can operate with confidence knowing they are using an internationally recognized and trustworthy system.

Monorail Hoists for Sale:

Monorail hoists are essential equipment in assembly lines that require the lifting and transportation of heavy loads. DQCRANES supply different types of monorail hoists for sale, each designed to meet specific needs and requirements.

Electric chain hoists are one of the most common types of monorail hoists used in assembly lines. They are designed to lift loads weighing from 200kg to 35 tons and can be used for both light and heavy-duty applications. Electric chain hoists are powered by an electric motor that drives a chain to lift the load. They are easy to operate, reliable, and require minimal maintenance.

- Wire Rope Hoist

Wire rope hoists are another type of monorail hoist commonly used in assembly lines. They are designed to lift loads weighing from 1 ton up to 80 tons and are ideal for heavy-duty applications. Wire rope hoists use a wire rope to lift the load and are powered by an electric motor. They are highly durable and can withstand harsh working conditions.

- Manual Hoist

Manual hoists are a cost-effective option for assembly lines that require occasional lifting of light loads. They are powered by hand and can lift loads weighing from 500kg up to 15 tons. Manual hoists are easy to operate, require no electricity, and are ideal for applications where space is limited.

Explosion-proof hoists are designed for use in hazardous environments where there is a risk of explosion due to flammable gases or dust. They are available in electric chain, wire rope, and air hoist options and can lift loads weighing up to 50 tons. Explosion-proof hoists are highly durable, reliable, and meet strict safety standards.

In conclusion, choosing the right type of monorail hoist for your assembly line is crucial for ensuring efficiency, safety, and productivity. Consider factors such as load weight, working environment, and frequency of use when selecting a monorail hoist. Contact DQCRANES today, will help you choose the right type of monorail hoist to increase productivity.