Cantilever cranes are an economical solution for moving materials within individual work areas or from one work area to another. They can also serve as auxiliary lifting devices under overhead cranes. There are a variety of Cantilever cranes on the market today, with styles ranging from entirely self-supporting to ceiling/bridge or wall-mounted.

When selecting a Cantilever crane that matches your individual requirements, it’s important to think about your operation type, facility structure, cost of the unit and installation, and any necessary options, like motorized rotation, box track festooning, boom locks, and rotation stops.

More specifically, the following factors should be considered when choosing the right Cantilever crane for your specific application:

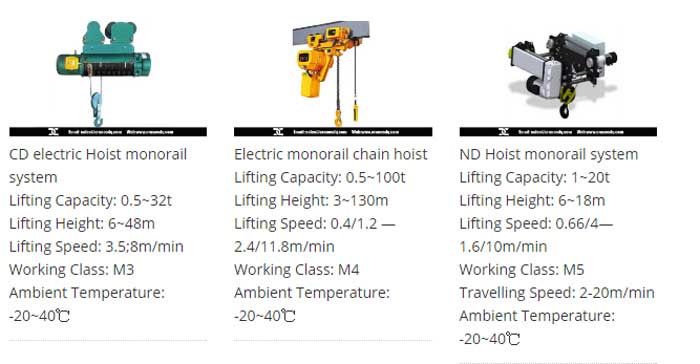

Capacity

The maximum weight of the application should never exceed the rated capacity/design weight. The capacity rating is based on a design load that includes the capacity rating of the crane plus 15 percent of the capacity for the weight of the hoist and trolley and 25 percent of the capacity to allow for additional impact. The deflection is based on a design load that includes the capacity plus 15 percent of the capacity for the hoist and trolley. Ensure your manufacturer is using design criteria that allows the least amount of deflection so as not to hamper the performance of the crane.

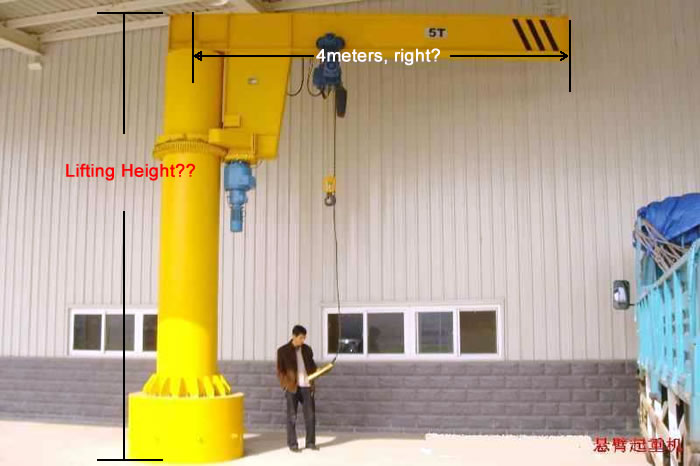

Height Under Boom (HUB)

The distance from the floor to the underside of the boom. It’s important to consider the size of the hoist and the amount of lifting distance when deciding on your HUB.

Overall Height

The height to the highest point on the crane after installation. Any attachments, such as electrical entry, should also be considered to provide full rotational potential and freedom from overhead obstructions.

Working Span

Distance from the floor to the underside of the Cantilever crane’s boom. Also factor in the size of the hoist and the lift height needed. The working distance or hook distance is approximately one-half the trolley length from the end of the beam and the same distance from the head assembly or vertical support member of the jib.

Boom Rotation

Freestanding and mast-type Cantilever cranes provide 360-degree rotation. Wall-mounted jibs offer 200-degree rotation, and articulating jibs provide 360-degree rotation on the inner and outer arm (freestanding and ceiling-mounted) and 360-degree rotation on the outer arm and 200-degree rotation on the inner arm (wall-mounted).

Power Requirement

How much power is necessary? Is the power for rotation, trolley, hoist, or all three? (Standard powered jib rotation is approximately 1/2 R.P.M). How will the power be supplied? Bottom or top entry? Electric or air?

Weatherization

Does the system or its electrical components need to be weatherized for outdoor use?

Installation

Can the crane be assembled easily to reduce cost? The location will also dictate the type of crane to be selected to insure proper installation. Freestanding jibs require reinforced concrete foundations which can cost more than the crane itself.

Because they are self-supporting, freestanding Cantilever cranes are well suited for outdoor use and can be fully weatherized.

For more information about selecting the proper Cantilever crane for your unique application, contact us for more information on the cantilever crane selection.