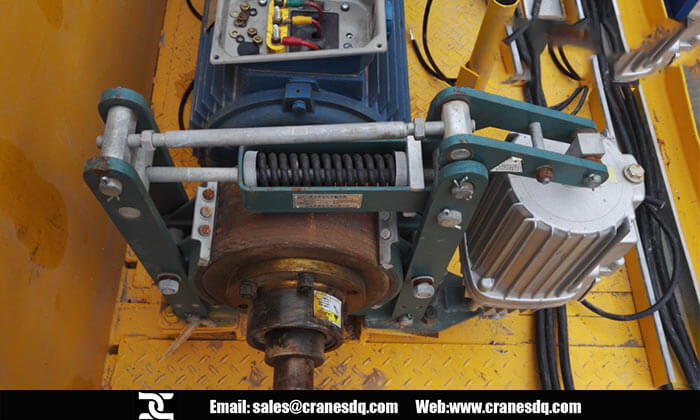

In daily inspection of special equipment inspection work, often come into contact with double beam crane brakes, crane brake device configuration is in line with the actual relationship to the service life of equipment and the use of security. Therefore, it is necessary for the crane brake device configuration are discussed. Standard series of braking device commonly used cranes include hydraulic block crane brake, electromagnetic block crane brake, disc crane brake, band crane brake, etc., its use to consider general type, specification, and check calculation, also want to consider using the environment and related factors.

Crane brake of double girder crane type choice, mainly according to the requirements of the lift machine or agency product standards and actual needs, determine the type of crane brake. As standard: lifting mechanism, luffing mechanism must be set close-type crane brake, often walk or slewing mechanism can choose often close-type crane brake. Consider using places, such as crane brake installation has enough space, can choose to block, band crane brake or arm type disc crane brake; Space limit, can choose the shoes or clip-on disc crane brake. Consider supporting the use of the host environment, the leakage of oil have strict requirements of occasions should choose electromagnetic or pneumatic crane brake, the environmental temperature high metallurgical places can choose insulation class higher power hydraulic crane brake or metallurgical type electromagnetic crane brake. In the environmental temperature is lower or higher, when choosing electric hydraulic crane brake and open Spaces, replace the corresponding brand of hydraulic oil should be paid attention to. In the iron filings and dust serious environment, should avoid to use electromagnet crane brake, prevent dust from entering the electromagnet gap influence electromagnet suction. For special or important occasions, should according to the need to add additional function of the crane brake. In low temperature environment, can use electric heater of hydraulic driver. For conversion start and crane brake process has strict requirements, equipped with state of the switch in order to understand the opening of the crane brake. For environment maintenance, adjustment more difficult to implement, can be mounted to the equality of device and friction wear crane brake clearance self-compensation device. Add manually loose crane brake device can under special circumstances artificial open the crane brake.

In order to alleviate crane brake wear, reduce impact and vibration because of the crane brake too hard, crane brake and crane brake control and recommended support. Crane brake of double girder crane is commonly electric braking control, such as regenerative braking, reverse connect braking, energy consumption braking and eddy current crane brake, etc. Electric braking is used only for kinetic energy consumption, make the organization safety deceleration. And electric braking use meantime, in support of crane brake minimum safety factor should be meet the provisions of the original alone. Also can use the secondary braking to reduce wear and impact, crane brake used in kinetic energy consumption for the first time, make the mechanical safety to slow down and stop, the second crane brake to ensure support security, such as for wind crane brake. The standard provisions of the state: to hook crane, when lifting mechanism work level equal to or higher than the M4 and rated lifting speed is equal to or higher than 5 m/min, the electric braking method should be adopted, guarantee (0.2 1.0) times the rated lifting weight falls within the scope of the load, crane brake motor droop to synchronous speed before 1.3 below. Conventional standard crane brake work environment cannot have inflammable, explosive and corrosive gas, such as the relevant provisions of the environmental conditions beyond, should choose the explosion-proof type crane brake.

Crane brake of double girder crane specification was determined, in order to ensure crane brake can effectively work or support load, and avoid the impact of braking distance is too long or crane brake too hard, should check the crane brake average deceleration, braking time and braking distance. Equipment used in different working condition, the relevant standards to the appropriate agency of average deceleration, braking time and braking distance are made clear rules. For the vertical crane brake of the crane brake and the crane brake in frequent use in high temperature environment should be heat calculation, a crane brake inspection under the maximum allowable temperature send out quantity of heat is greater than the heat generated by the braking process, in order to avoid friction surface overheating damage or failure.