Explosion Proof Hoists to Pakistan Coal Mines

Client Industry: Coal Mining

Location: Pakistan

Supplier: DQCRANES

Equipment Delivered: 6 Units Explosion-Proof Wire Rope Hoists

Delivery Date: April 6, 2025

Certifications: Explosion Proof Standard (Ex), ATEX/IECEx compliant

Project Background

With the increasing demand for safe and efficient material handling in hazardous environments, DQCRANES was commissioned to supply customized explosion-proof wire rope hoists for a coal mining project in Pakistan. The client, a major player in the country’s mining sector, required robust lifting solutions to operate safely in Zone 1 hazardous environments characterized by the presence of flammable gases and coal dust.

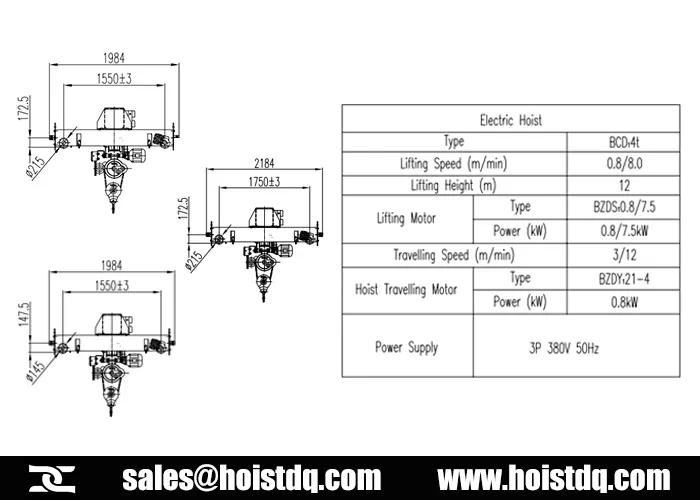

Explosion Proof electric hoist Specifications:

- Lifting Capacities: 1 Ton (x2 units), 4 Ton (x2 units), 5 Ton (x2 units)

- Lifting Height: 12 meters

- Lifting Speed: Dual speed – 0.8 m/min (low) / 8.0 m/min (high)

- Traveling Speed: 3/12 m/min

- Control Method: Remote and pendant control

- Protection Class: IP65

- Power Supply: 380V/3Ph/50Hz (customized per client specs)

- Application: Ex de IIB T4, Underground coal mining operations

Challenges and Solutions

- Harsh and Hazardous Environment

Coal mines are categorized as high-risk environments due to the constant presence of flammable gases. DQCRANES provided hoists built with explosion proof motors, enclosures, and wiring to prevent sparks and overheating, ensuring compliance with ATEX and IECEx standards.

- Versatile Lifting Requirements

The client required different capacities (1T, 4T, 5T) to handle varied underground lifting tasks. DQCRANES customized each unit to match the weight class, with reinforced mechanical brakes and overload protection systems to ensure safety and durability.

- Dual Speed Operation

Precision control was critical for positioning materials in confined underground spaces. The hoists were configured with dual-speed lifting (0.8/8.0 m/min) to allow both delicate operations and fast bulk lifting, paired with variable traveling speeds (3/12 m/min) for efficient workflow.

Why Explosion Proof Hoists for the Mining Industry?

Safety in Hazardous Environments

Mining operations, especially coal mines and underground shafts, often contain flammable gases (like methane) and combustible dust. Even a small spark from standard equipment can trigger a devastating explosion.

Explosion proof hoists are designed to:

- Contain sparks within sealed components (motors, wiring, controls)

- Prevent ignition of surrounding gases/dust

- Meet international safety standards such as ATEX, IECEx (e.g., Zone 1, Class I Div 1)

- Result: A drastically reduced risk of fire or explosion.

Compliance with Safety Regulations

Mining is one of the most heavily regulated industries for occupational safety. Government bodies and international standards mandate the use of explosion proof equipment in certain zones.

Explosion proof electric hoists for sale from DQCRANES are certified to:

- Operate in Zone 1 or 2 (gas), and Zone 21 or 22 (dust) environments

- Comply with mining safety codes, protecting your company from legal penalties or shutdowns

Durability Under Harsh Conditions

Mines are subject to High humidity, Dust ingress, Corrosive gases, and Extreme temperatures.

Explosion proof hoists are built with:

Enclosed motors and gearboxes

Heavy-duty steel construction

IP65 protection ratings

Anti-corrosion treatments

Result: Longer service life, less maintenance, reduced downtime.

Precision and Control

Explosion proof hoists often come with dual-speed lifting, variable traveling speeds, and remote/panel controls, which are essential in:

Confined spaces

Delicate material positioning

Multi-load handling in deep shafts

They also include features like:

Overload protection

Emergency stop systems

Brake safety interlocks

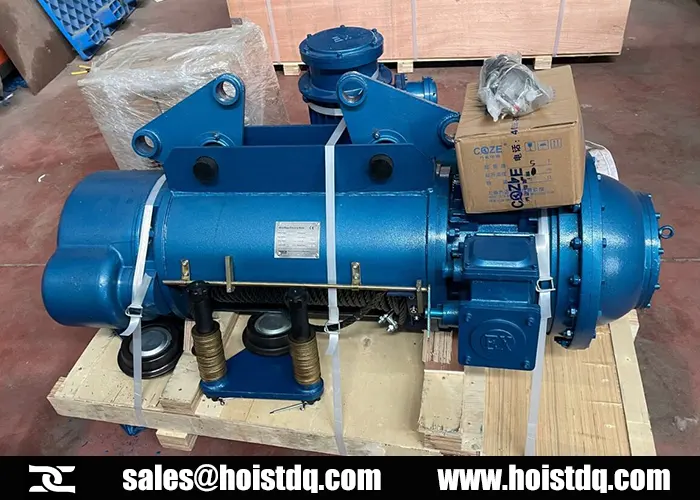

Manufacturing and Quality Assurance

All six units ex-proof hoists were manufactured at DQCRANES’ state-of-the-art facility, with rigorous pre-shipment testing including:

- Load testing up to 125% rated capacity

- Electrical insulation and grounding tests

- Explosion proof system validation

- Simulation of start/stop cycles under load

Each unit came with:

- Full documentation (manuals, test reports, certification)

- Spare parts package

- Remote commissioning support

Shipping and Delivery

The Ex-certified hoists for Pakistan mining were packed in marine-grade wooden crates with protective film for sea transport. The delivery to Karachi Port was completed within the agreed 6-week lead time, with custom clearance support and remote installation guidance offered by DQCRANES’ technical team.

Client Feedback

“DQCRANES delivered exactly what we needed – safe, reliable, and high-performance flameproof hoists. The flexibility in lifting speed and their technical support were impressive.”

– Project Manager, Pakistan Coal Mining Company

Explosion Proof Cranes & Hoists for Mining Industry

DQCRANES offers types of explosion-proof cranes and hoists commonly used in the mining industry, especially for environments with combustible dust and flammable gases like coal mines, metal ore operations, and underground shafts.

Explosion Proof overhead crane

- Type: Single or double girder

- Capacity: 1–100+ tons

- Explosion Proof Grade: Ex d IIB T4 (ATEX / IECEx)

- Application: Lifting heavy mining equipment, ore containers, or maintenance loads in hazardous areas

Explosion Proof gantry crane

- Type: Rail-mounted or mobile (A-frame, U-frame)

- Capacity: 1–50 tons

- Lifting Height: Customizable for underground or surface mine use

- Application: Outdoor or pithead lifting where overhead structures aren’t available

- Use Case: Transporting materials across uneven or open mining sites

Explosion Proof jib crane

- Type: Wall-mounted or pillar type

- Capacity: 0.5–15 tons

- Application: Compact, local lifting in hazardous workshops or maintenance areas in mines

- Explosion Proof Elements: Rotating arm motor, spark-proof wire rope hoist

Explosion Proof Wire Rope Hoist

- Capacity: 0.5–50 tons

- Lifting Speed: Single or dual-speed (e.g., 0.8/8.0 m/min)

- Traveling Speed: 2–20 m/min

- Explosion Proof Class: Zone 1 or 2 (gas), Zone 21 or 22 (dust)

- Application: Long-lift, heavy-duty applications underground

Explosion Proof Chain Hoist

- Capacity: 0.25–35 tons

- Application: Light to medium lifting in confined or narrow mining locations

- Design: Compact, easy to install on trolleys or fixed beams

- Explosion Proof Class: Ex d IIC T6

Explosion Proof Electric Trolley Hoist

- Integrated hoist + trolley system

- Ideal for monorail tracks in mining tunnels

- Smooth travel with explosion proof gear motors

- Variable frequency drive (VFD) is optional

Conclusion

This project exemplifies DQCRANES’ capability to provide customized explosion proof lifting solutions to meet the stringent safety requirements of the mining industry in hazardous zones. Whether for coal, oil & gas, or chemical applications, DQCRANES continues to lead with engineering excellence, compliance, and service reliability. Contact us now, we’ll send a detailed quotation and technical proposal within 24 hours.