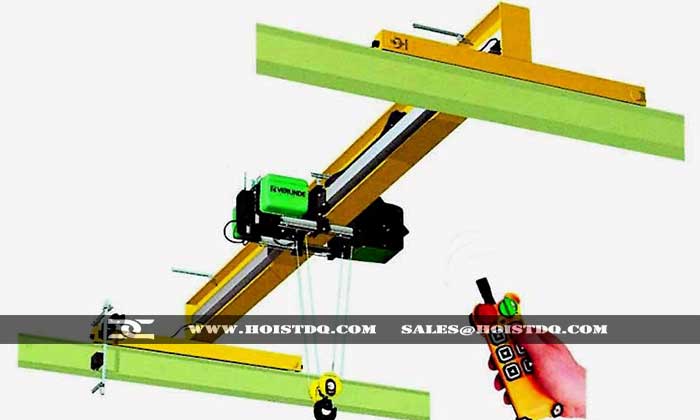

Under hung overhead crane

Underhung Overhead crane is your flexible material handling solution.

Under hung crane, also called under slung overhead crane or under running overhead crane, which is designed for flexibility and functionality. Because the under hung crane system is usually lighter than top running overhead crane system, so a under hung overhead crane can be hung in the building structure directly without support. Compared with top running overhead crane, under hung crane is more suitable for factory that height is limited.

An Underhung Overhead crane, or under-running overhead crane rides on the lower flange of the beam, comparing with a top running overhead crane. An Underhung Overhead crane outcomes the top running crane in that the Underhung Overhead crane experiences fewer tracking problems than a top-running crane due to the underhung crane is bolted to the I-beam, which is secured to the building structure. Whereas, it also limits the overhead crane crane’s movement and lessens the chances of rail misalignment.

But when an underhung crane system does require realignment, the required downtime may be greater than for a top-running crane system, due to suspension and rigging required for alignment of an underhung system. In contrast, while top-running crane systems require more frequent rail alignment checks and more frequent rail alignment, they are easier service.

Features of Underhung Overhead crane

- 1. Ceiling supported runway system for under running cranes will maximize usable floor space

- 2. Most commonly used in light to medium duty cycle applications

- 3. Can have longer crane spans with 2, 3 or even 4 runway beams to support the under running crane system

- 4. Under running cranes are most commonly used in assembly plants, fabrication shops, maintenance areas and manufacturing facilities

- 5. The under hung is designed to lift 10 tons or less (some particular overhead crane up to 25 tons available) materials.

Advantages of under hung overhead crane

1. Easily manipulate even in wide bay, minimizing the depth of bridge beam, and leaving the lighter lifting equipment. Therefore, plenty of space can be saved, as well as lots of capitals will be cut down.

2. Independent operation that don’t influence the overall or other running.

3. It can lift or transport materials along with a fixed road, which offer large convenient for production procession.

4. Maximum use the space of building.

5. Using the existing ceiling girder to increase the safety of crane track.

6. Best deal with the situation that headroom is low and maximum the distance from ground to the hook.

7. All-around guidance on installation and maintenance.

8. Advanced technology and reasonable design

9. Profound appearance and strong steel structure

10. Thoughtful service and competitive price.

When buying an Underhung Overhead crane

When buy an Underhung Overhead crane, the following should be considered:

Is your building’s structure strong enough to support a crane system? If not, a freestanding overhead crane system is an option. The drawback of a freestanding underhung crane system is that it takes up floor space from production and other uses. Contact Dongqi Hoist and Crane for more information on the Underhung Overhead crane.

Underhung overhead crane of Dongqi Hoist and Crane

European standard Underhung Overhead Crane

European standard Underhung Overhead Crane parameters

Lifting Capacity: 3.2~16t, Span Length: 7.5~28.5m

Lifting Height: 6~12m, Lifting Speed: 0.66/4-1.6/10m/min

Trolley Speed: 2-20m/min, Working Class: A5

Ambient Temperature: -20~40℃

HD type European standard Underhung Overhead Crane

HD type European standard overhead crane of parameters

Lifting Capacity: 3.2~16t, Span Length: 7.5~28.5m

Lifting Height: 6~12m, Lifting Speed: 0.66/4-1.6/10m/min

Trolley Speed: 2-20m/min, Working Class: A5

Ambient Temperature: -20~40℃

LB type explosion-proof Underhung Overhead Crane

LB type explosion-proof Underhung Overhead Crane parameters

Lifting Capacity: 1~20t, Span Length: 7.5~28.5m

Lifting Height: 6~18m, Working Class: A3, A4

Explosion-proof Grade: ExdⅡBT4 / CT4

LDP Hoist Underhung Overhead Crane

LDP type partial hoist Underhung OverheadCrane parameters

Lifting Capacity: 3~10t, Span Length: 7.5~22.5m,

Lifting Height: 3~30m, Working Class: A3 A4,

Ambient Temperature: -25~40℃

LDY Metallurgy Single Girder Underhung Overhead Crane

LDY Metallurgy Single Girder Underhung Overhead Crane parameters

Lifting Capacity: 1~20t, Span Length: 7.5~28.5m,

Lifting Height: 6~18m, Lifting Speed:7-8m/min

Crane Speed: 20-30m/mim, Working Class: A6

Ambient Temperature: -20~40℃

Contact Dongqi Hoist and Crane for more information on the underhung crane now.