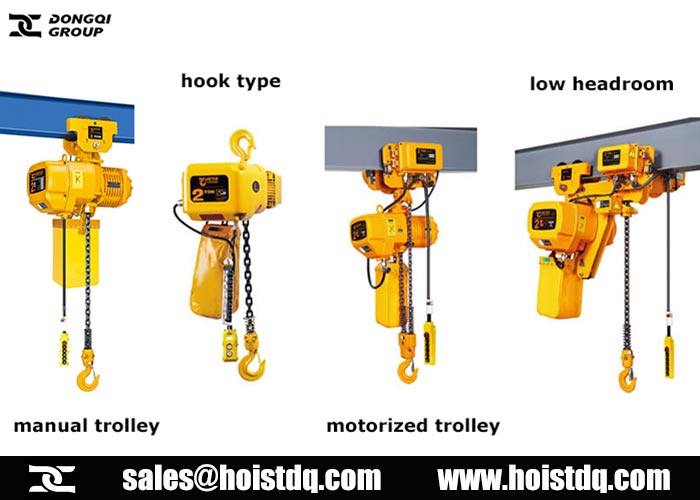

Variable speed hoist

Variable speed hoist is a small-sized lifting equipment, which is installed on the single girder, bridge cranes, gantry cranes, jib cranes for material handling. As one of the commonly used material handling equipment, the variable speed hoist is usually used in factory, mining, railway, port, and storage, etc.

The variable speed hoist has two speed options which coordinate with each other to realize the efficient material handling work with precision. The lifting capacity of variable speed hoist is 0.5 – 32 ton and the working class is M3 and M4.

The main parameter of variable speed hoist is as follow:

- Variable Speed Hoist Product Type: MD1

- Variable Speed Hoist Lifting Capacity : 0.5~32t

- Variable Speed Hoist Lifting Height: 6~50m

- Variable Speed Hoist Working Class: M3,M4

- Variable Speed Hoist Ambient Temperature: -25~40℃

Advantages of Variable speed hoist

Variable speed hoist of Dongqi hoist and crane has the following advantages:

- The variable speed hoist is designed with compact structure, with the features of small size, light weight, standardized parts, etc.

- The variable speed hoist has fast and slow lifting speed, which can make the lifting stable and easy.

- The variable speed hoist has big lifting capacity, high working efficiency, and long working life.

- The variable speed hoist is easy to operation and convenient to repair.

Features of Variable speed hoist

The variable speed hoist from DQCRANES has the following features:

-

On lifting motor.

The lifting motor of variable speed hoist is a bigger moment motor of taper rotor, with asynchronous braking, thus the extra braking is needed. The motor loading lasting rate is 25%, ensuring high safety.

The lifting motor of variable speed hoist has the B or F grade insulation and the safety class of IP44/ P154.

-

On Lifting Speed Reducer

The lifting speed reducer of variable speed hoist adopts Class 3 dead axle bevel wheel, with a long working life. The gear is made of heated alloy steel with high intension.

Tank body and tank cover of the reducer are made of best cast iron, strictly assembled and sealed well. The reducer is a separate device, which is convenient to be installed and uninstalled.

The lifting speed reducer has a very high efficiency and high reliability during moving.

-

Protect Function

Safety is always the concern of DQCRANES. Our hoisting equipment is equipped with various devices to ensure the safety of hoist and operators. The variable speed hoist is matched with brennschluss stopper, to ensure the safety of hoist during moving. The hoist also installed with head punch protection device.

-

Wire rope.

The wire rope used is confirming with the national standards GB/T 20118-2006(6*37+1), which has good resistance to wear.

-

Operation device

The variable speed hoist has two operation devices: the wire rope operating and remote control. It is very light and handy.

electric hoist double speeds makes your material handling work precise and efficient. Amazing variable speed hoist with amazing price for sale now! Contact us for more information on the variable speed hoist.

Precautions before variable speed hoist application

The new installation variable speed hoist should be testing with empty load several times. But testing should not be done before installation work finished.

- Before the variable speed hoist put into usage, the electric hoist should be tested by lifting 125% load above ground level 100mm for 10 minutes’ time to check whether it is qualified.

- Dynamic load test for the variable speed hoist is to lift rated capacity load repeatedly in every direction, after dynamic load test, all the mechanical and electrical components should be checked to see whether all components is qualified.

- Among variable speed hoist usage, the following circumstances is prohibited: overload lifting, lift more than 120 times in one hour, operation under prohibited environment.

- Among the variable speed hoist installation and maintenance, the limit switch device should be strictly checked in qualified state, when the hook is at upper limit position, the distance from hook shell to drum shell should be more than 50mm(10t,16t and 20t hoist should be more than 120mm). When the hook is at lower limit position, the wire rope should have at least 2 effective laps on the drum.

- It is prohibited to press two opposite movement button at the same time.

- When the variable speed hoist is off duty, cut off the power.

- The variable speed hoist should be operated by professional person, the hoist operator should be aware of all the safety operating rules, non-straight lifting operation should be strictly prohibited.

- Regular maintenance should be done among electric hoist usage, timely measures should be taken if any problem happens, and take record carefully.

- There should be enough lubrication oil among hoist usage, and keep the oil clean without any dirt.

- Stiff brush or small piece of wood should be used to make the wire rope oiled, directly by hand is prohibited.

- When variable speed hoist is off duty, it is prohibited to hang load in the air, in order to prevent deformation.

- If any problem happen among operation, the variable speed hoist should be cut off power immediately.

- After continuous operation of 10~20Ton variable speed hoist, automatic power-off circumstance may occur, it is a function of the motor overheating protection, when this circumstance happens, the operation should be stopped till the motor becomes cool down.

Hot hoisting equipment

Dongqi Hoist and Crane Videos

Contact info

- Email: sales@hoistdq.com

- Sales Tel: +86-371-86687182

- Fax: +86-371-86687182

- Whats App : +86 18838184113